As we all know, the Internet refers to the global public network, which is made up of many networks connected to each other. Currently, the first generation of Web1.0 refers to the early days of the Internet, which lasted from 1994 to 2004 and included the emergence of social media giants such as Twitter and Facebook. It is mainly based on HTTP technology, which shares some documents on different computers openly and makes them accessible through the Internet. Web1.0 is read-only, there are very few content creators, and the vast majority of users simply act as consumers of content. And it is static, lack of interactivity, access speed is relatively slow, and the interconnection between users is quite limited; The second generation of the Internet, Web2.0, is the Internet used from 2004 to the present. The Internet will undergo a transformation around 2004, due to the development of Internet speed, fiber optic infrastructure and search engines, so users' demand for social networking, music, video sharing and payment transactions has increased dramatically, ushered in the explosive development of Web2.0. Web2.0 content is no longer produced by professional websites or specific groups of people, but by all Internet users with equal rights to participate in and co-create. Anyone can express their opinions or create original content on the Internet. Therefore, the Internet in this period is more focused on user experience and interactivity; The third generation of the Internet, Web3.0, refers to the next generation of the Internet, will be based on artificial intelligence and blockchain technology to promote a new form of the Internet.

Web3.0 is based on blockchain technology, and one of its biggest features is decentralization. Blockchain technology has given birth to a new thing called smart contract, it can not only record information, but also run applications, the original need to have a centralized server to run the application, in blockchain technology, do not need the server center, they can run, which is called decentralized application. So it is now also known as the "Smart Internet", as shown in Figures 1 and 2. What is the Industrial Internet? In short, it refers to the industrial application based on Internet technology, connecting various departments, equipment, logistics, etc., within the enterprise through network technology to achieve information sharing, interaction and collaboration, in order to improve production efficiency, reduce costs, and optimize business processes. Therefore, with the development of the first generation, the second generation and the third generation of the Internet, there is also the development of the industrial Internet era. What is an Internet platform? It refers to a technology platform built on the basis of the Internet, which can provide various services and functions, such as search engines, social media, e-commerce platforms, online education, manufacturing services, and so on. Therefore, with the different times of the development of the Internet, there are industrial Internet web2.0 and web3.0 platforms. At present, the industrial Internet service platform used by the manufacturing industry mainly refers to the web2.0 platform, the application of this platform has its advantages, but there are also many shortcomings, and now countries are developing to the web3.0 platform on the basis of the web2.0 platform.

The development of industrial Internet and its platform in web2.0 era in China

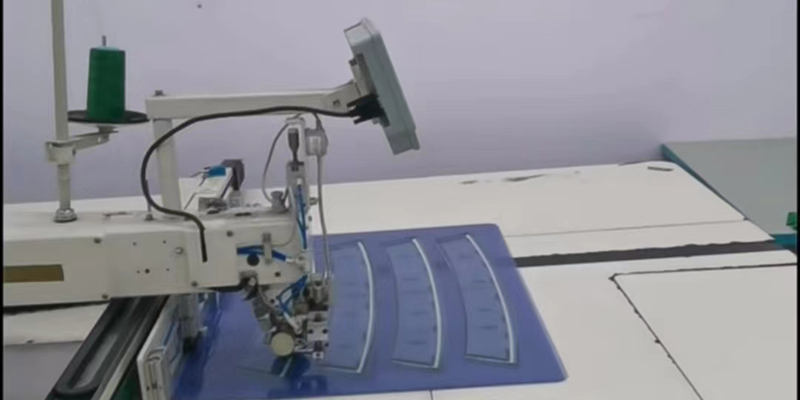

China's industrial Internet is in the network, platform, security three systems to achieve large-scale development, by the end of 2022, the national industrial enterprises key process numerical control rate and digital R & D tool penetration rate reached 58.6%, 77.0%, basically formed a comprehensive, characteristic, professional multi-level industrial Internet platform system. At present, the 35 key industrial Internet platforms in China have connected more than 85 million sets of industrial equipment and served 9.36 million enterprises in total, covering 45 industrial sectors of the national economy. New models and business forms such as platform design, digital management, intelligent manufacturing, networked collaboration, personalized customization, and service extension are flourishing. The digital transformation of China's industry has significantly accelerated.

At present, the application of industrial Internet integration has extended to key industries of the national economy, forming six aspects of platform design, intelligent manufacturing, network collaboration, personalized customization, service extension, and digital management, which has effectively promoted the quality, efficiency, cost reduction, green and safe development of the real economy. Table 1 shows a panorama of the development of the industrial Internet for a number of industries and enterprises, including textile and garment manufacturing enterprises.

Table 1 Panorama of industrial Internet development in some manufacturing enterprises

The industrial Internet platform is a service system based on mass data collection, aggregation and analysis for the digitalization, networking and intelligence needs of the manufacturing industry, which supports the ubiquitous connection, flexible supply and efficient allocation of manufacturing resources. From an economic point of view, this has formed a valuable platform for the industrial Internet. It is said that the industrial Internet platform is valuable mainly because it has three obvious functions: (1) On the basis of traditional industrial platforms, the industrial Internet platform has improved the production, dissemination and utilization efficiency of manufacturing knowledge, developed a large number of application apps, and formed a two-way interaction ecosystem with manufacturing users. The industrial Internet platform is the "operating system" of the new industrial system. The industrial Internet platform relies on efficient equipment integration modules, powerful data processing engines, open development environment tools, and component-based industrial knowledge services

It connects industrial equipment, instruments and products downward, supports the rapid development and deployment of industrial intelligent applications upward, and builds a new industrial system based on software that is highly flexible and intelligent. (3) Industrial Internet platform is an effective carrier of resource agglomeration and sharing. The industrial Internet platform brings together information flow, capital flow, talent creativity, manufacturing equipment and manufacturing capabilities in the cloud, and gathers industrial enterprises, information and communication enterprises, Internet enterprises, third-party developers and other entities in the cloud, forming a socialized collaborative production mode and organization model.

On November 30, 2021, the Ministry of Industry and Information Technology issued the "14th Five-Year Plan for the In-depth Integration of Informatization and Industrialization" (hereinafter referred to as the "Plan"), which clearly promoted the industrial Internet platform promotion project as a key project of the integration of the two. From the point of view of the physical system, the industrial Internet platform is composed of three parts: network, platform and security, and its application in the manufacturing industry is mainly reflected in the manufacturing services such as digital intelligent production, network collaboration, and personalized customization.

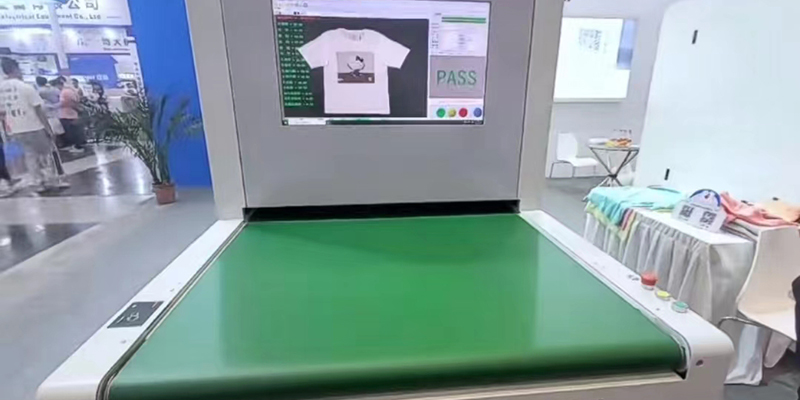

The application of industrial Internet platform services in manufacturing industry can obtain much higher benefits than general software and general industrial cloud, as shown in Figure 2. The application of industrial Internet platform services in China's manufacturing industry can obtain quantifiable high returns, which can be expressed by one plus one minus, such as one plus: labor productivity increases by 40-60% and equipment comprehensive efficiency increases by 10-25% and so on; A reduction in energy consumption by 5-25% and delivery time by 30-50%, etc., see Figure 3.

Today, the main service models in the industrial Internet web2.0 era in China are :(1) the export platform service model of leading manufacturing enterprises, such as the "manufacturing knowledge, software, hardware" triad of MEicoqing Industrial Internet Service Platform, Haier's Industrial Internet service platform built on the basis of personalized customized production mode. The cloud network of Aerospace Group is an industrial Internet service docking platform based on the integration and coordination of upstream and downstream resources of the industry. (2) Some industrial Internet companies provide customers with software application service models in the form of SAAS cloud platform, and the products mainly focus on vertical application development in various subdivisions, focusing on solving a pain point in the production or operation process of the vast number of small and medium-sized manufacturing enterprises; (3) Create a general PAAS platform service model, through which all equipment, production lines, employees, factories, warehouses, suppliers, products and customers related to the enterprise can be closely connected, and then share various elements of the whole process of industrial production resources, making it digital, networked, automated and intelligent. Ultimately achieve enterprise efficiency and cost reduction services. Of course, we know that although there are many models, it is not easy to achieve success, because for each manufacturing industry, the production of things are not the same, the process is not the same, the process is not the same, the equipment is not the same, the channel is not the same, and even the business model and supply chain are not the same. In the face of such needs, it is very unrealistic to solve all problems through a universal service platform, and eventually return to highly customized, which may require an industrial Internet platform in every subsector.

In May 2023, the "Industrial Internet Platform Selection Requirements" (GB/T42562-2023) national standard led by the China Institute of Electronic Technology Standardization was officially approved and released, the standard first stipulates the selection principles and selection process of the industrial Internet platform, see Figure 4; Secondly, it defines nine key technical capabilities that the industrial Internet platform should meet, as shown in Figure 5. Secondly, 18 business support capabilities based on platform for enterprise empowerment are defined, as shown in Figure 6. The publication of this standard can adapt to the different relevant parties of the platform, it can provide the ability to build the platform for the industrial Internet platform enterprises, it can provide a reference for the demand side of the manufacturing industry to choose the platform, help enterprises evaluate the level of industrial Internet platform empowerment, and choose the appropriate industrial Internet platform for themselves.

If the apparel manufacturing industry chooses a platform to serve the intelligent manufacturing of enterprises, it is generally carried out in accordance with the process in Figure 4. At present, the best architecture for implementing intelligent manufacturing of apparel should be shown in Figure 7, with a good infrastructure layer, platform layer, application layer and edge computing layer.

The above platform architecture is built on the basis of the industrial Internet web2.0 platform, we have said in the past, clothing manufacturing enterprises above the scale to build their own web2.0 platform is good, small and medium-sized manufacturing enterprises to rent platform services is good, in fact, this statement is not completely correct, Because choosing to build your own web2.0 platform or rent platform services should be decided according to the specific situation and needs of the enterprise, rather than solely based on the size of the enterprise. Secondly, manufacturing enterprises do not use the industrial Internet platform web2.0, and can still achieve intelligent manufacturing by other means, such as using self-built data transmission and analysis systems, or using other third-party platforms. However, in comparison, the industrial Internet platform web2.0 has higher scalability and flexibility, and can better meet the needs of manufacturing enterprises.

Intelligent clothing manufacturing will be implemented on the intelligent Internet web3.0 platform.

From the above, we can see that although the Web2.0 platform based on the industrial Internet has many characteristics: (1) high user participation - the Web2.0 platform allows users to participate and interact, so that users can share their own content and experience, interact with other users, and form a large community; (2) Easy to share and disseminate -Web2.0 platform allows users to easily share and disseminate information, thus expanding the scope of information dissemination; (3) Improve efficiency -Web2.0 platform can help enterprises improve efficiency, such as through online collaboration tools, online meetings and other ways to improve the efficiency of internal collaboration; (4) Reduce costs -Web2.0 platform can help enterprises reduce marketing, promotion and customer service costs, but also reduce the cost of technology and so on. However, the web2.0 platform also has many shortcomings: (1) security issues - there are security risks in the Web2.0 platform, such as privacy disclosure, network attacks and other problems, which requires enterprises to strengthen security measures; (2) Quality issues - the content quality of the Web2.0 platform is uneven, requiring enterprises to screen and review the user-generated content; (3) Fierce competition - the Web2.0 platform is highly competitive, which requires enterprises to spend a lot of time and energy to promote and maintain the platform; (4) Network stability -- the Web2.0 platform needs to ensure network stability to avoid network failure affecting the normal operation of the platform; (5) Web2.0 platform services have a certain monopoly, and the rental cost is high, affecting the use of enterprise users and so on. It is because of these problems that the web3 platform was born. Web3.0 is the next generation of Internet development, sometimes referred to as the "distributed Internet" or the "smart Internet". At present, Web3.0 is still in the early stage of development, but it will rely on blockchain, artificial intelligence, Internet of Things and other technologies to achieve more intelligent and decentralized Internet applications, so that data is more secure, privacy is more protected, and users are provided with more personalized and efficient services. Therefore, the implementation of intelligent manufacturing on the web3 platform is different from the implementation of intelligent manufacturing on web2, the difference is that: (1) decentralization - the Web3 platform is based on blockchain technology and realizes the characteristics of decentralization. This means that smart manufacturing implemented on the Web3 platform will be more decentralized and democratized, with no centralized control body. Each participant can own and control their own data without relying on centralized platforms or institutions; (2) Data privacy and security - The Web3 platform focuses on the privacy and security of user data. Blockchain technology provides the features of encryption and decentralized storage, making user data more secure. When smart manufacturing is implemented on the Web3 platform, it can better protect the privacy of users and prevent the abuse of data. Trust and transparency - The Web3 platform achieves greater trust and transparency through mechanisms such as smart contracts. A smart contract is a self-executing contract whose rules and conditions are encoded on the blockchain and cannot be tampered with. In this way, smart manufacturing implemented on the Web3 platform can be more transparent, and participants can verify and audit the operation and transactions of the system; (4) Value exchange - the Web3 platform's token economic model based on blockchain technology makes value exchange more convenient and efficient. Smart manufacturing implemented on the Web3 platform allows for value exchange through tokens, more flexible business models and ways of cooperation, and more. In summary, smart manufacturing implemented on the Web3 platform is more focused on decentralization, data privacy and security, trust and transparency, and value exchange than the implementation on the Web2 platform. These characteristics bring greater innovation and development space for intelligent manufacturing. The Web3.0 platform is closely related to the intelligent manufacturing of our clothing manufacturing enterprises, because the essence of Web3.0 is the intelligent Internet based on artificial intelligence and blockchain technology, which will provide more intelligent, efficient and secure technical support for intelligent clothing manufacturing, thus promoting the rapid development of intelligent clothing manufacturing. Specifically, the application of Web3.0 technology in intelligent clothing manufacturing mainly includes the following aspects: (1) Data sharing - Based on Web3.0 technology, clothing manufacturing enterprises can realize data sharing among various equipment, production lines, employees, etc., so as to achieve a more efficient production and manufacturing process; (2) Blockchain technology - Through blockchain technology, clothing manufacturing enterprises can realize the safe sharing of data, avoid data tampering and leakage problems, and improve the credibility and security of data; (3) Smart contracts -Web3.0 can also realize automated and intelligent production and manufacturing processes through intelligent technology, improving production efficiency and product quality; (4) Intelligent Internet of Things -Web3.0 technology can realize the application of intelligent Internet of Things, so that manufacturing enterprises can monitor and control various equipment and data in the production process in real time, thereby improving production efficiency and product quality. Therefore, Web3.0 is closely related to the intelligent manufacturing of clothing manufacturing enterprises, and it will provide a broader space and more intelligent, efficient and secure technical support for the development of intelligent manufacturing.

Post time: Aug-08-2023